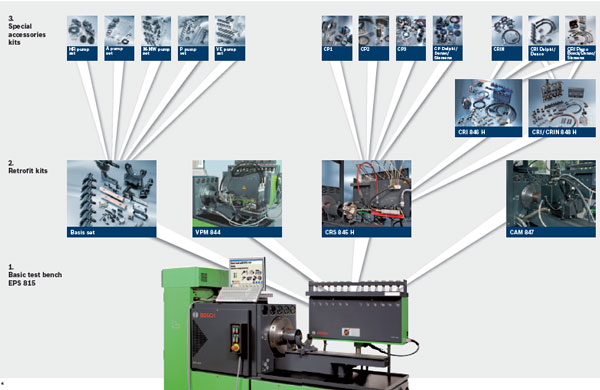

Test virtually all brands of diesel pump and injectors!

Conventional system

- H-type pumps

- R-type pumps

- A-type pumps

- M-MW-type pumps

- P-type pumps

- VE-type pumps

Solenoid-valve-controlled system

- VP 29-type pumps

- VP 30-type pumps

- VP 44-type pumps

Unit injector / unit pump system

- Unit Injector-P

- Unit Injector-N

- Unit Pump

Common Rail System

- CP1, CP2, CP3, CP Delphi / Denso / Siemens

- Solenoid valve CRI Bosch / Delphi / Denso

- Solenoid valve CRIN Bosch

- Piezo CRI Bosch / Siemens / Denso

The forward-looking design of the test bench allows diesel specialists to test high-performance components of the latest generations both from Bosch and other manufacturers. This is guaranteed by the add-on capacity of the EPS 815 with for example: MGT/KMA, VPM 844/CRS 845/CRI 846/CAM 847, CP 1/2/3/CRIN and external systems

The specifications of the automobile manufacturers and the statutory emission regulations are observed. In addition, the testing of future diesel injection components will be guaranteed by the permanently improved versions of optional accessories.

- Environmental and user-friendliness is achieved by means of a reduction in oil gas and oil mist.

- Outstanding true-running characteristics and speed stability ensure high reproducibility, specially during the injection cycle: Direct drive, High flywheel mass, Rotational-speed control with an extremely short speed control time, Position control

- Maintenance-free drive element with high efficiency

- The weight counterbalance during height adjustment of the measuring device makes work considerably easier

- Longer service life, because hardly any rebending work is required on the test pipes (the measuring device can be adjusted on all three levels)

- Fully-automatic test sequence in connection with KMA 802/822. Very user friendly! This testbench is almost completely computer-controlled.

KMA 802/822

After the pump is overhauled and mounted on the testbench, the operator just punches in the pump assembly number on the computer then the EPS815 does the rest. Without user intervention, it runs the pump through all the necessary tests, then it increases and decreases the fuel where its needed. If at any point during the cycle the pump fails a test, the testbench will stop and inform the operator to make the specific necessary steps to correct the repair, and proceed with the calibration

System features

- Computer measuring system for pumps up to 12 cylinders

- Large memory for test values and measurement results

- Colour screen for graphic display of measured data

- Tolerance deviations are accentuated in color

- Short measurement time through running capturing of the injection volumes

What can all these do for you?

The hardware and ESItronic software and test data will permit you to simulate all necessary operating states of normal vehicle operation. For engines equipped with the electronic VP44 pumps for example, you would be surprised how many setting are important to assure that everything is within the specifications set by both the engine and fuel injection system manufacturer -- like starting, idling, partial load and full load, and everything in between.

Everything you need to properly repair or calibrate virtually all mechanical, electronic and commonrail diesel pumps and injectors. Equipment that will not drain your cash flow. Superior equipment that would help you jump ahead of the pack…and stay ahead.

Please click here for the EPS815 brochure.