The purpose

The introduction of modern high-pressure diesel injection systems has led to an increase in the demands on workshops.

Absolute cleanliness is a requirement for installing and removing components, and during testing and repairs. We need to ensure a ‘dust-free’ working environment for high pressure diesel fuel injection component repair.

Bosch PH asked us to set up a Cleanroom in Malabon Diesel for CRI/CRIN/UI/UP repair. We said yes.

Like those found in semiconductor and pharmaceutical manufacturing facilities, we commissioned a cleanroom contractor to build one.

How good is it?

It can filter particles as small as 1 micrometer. For reference, a hair strand is usually 80 micormeters in diameter.

Scrub suits are required to maintain cleanliness.

Commonrail injector assembly is done inside the cleanroom. "Third-stage" automatic measurement equipment ensure that standards are exactly met.

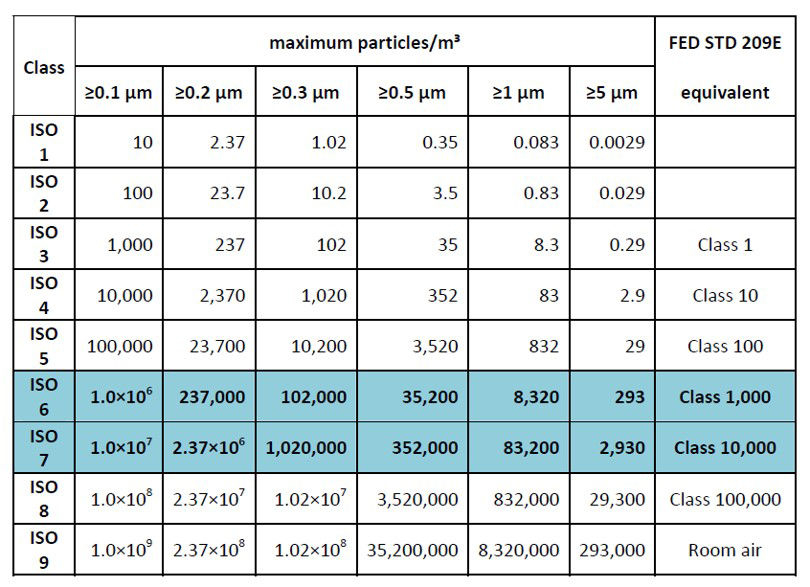

ISO 14644‐1 cleanroom standards

We now have a class 400 at 1 micrometer particle size clean room (Room classification between class 1,000 and class 10,000).

Testing

Does it really meet Bosch cleanroom standards?

How the cleanroom is tested:

- Air Velocity

- Filter Integrity test using Emery 3004 Challenge

- 3-point Particle Test

- 1-point Temperature and Relative Humidity Test

- 1-point Room Pressure Test

It is the first and only cleanroom in the PH diesel repair industry. And we are very happy that we built one for you.

Further readings:

Malaya Business Insight. December 16, 2014. Click here.

Top Gear Philippines. December 9, 2014. Click here.

https://malabon-diesel.com/us/why-us/cleanroom.html#sigProId12ee847811